Introduction to the use of EVA in glass lamination

EVA-based encapsulants are widely used in the photovoltaic industry but also for specific architectural glass applications it might be interesting to consider EVA interlayers. These materials are not a direct competition to the widely used PVB interlayers for safety glass, but they find an application in specific niche projects where the specific nature of (formulated) EVA polymers can have a benefit. In what follows, the chemical background of EVA polymer interlayers will be discussed. As there are important differences between the chemistry of EVA and PVB, it is important to dive deeper into the chemical aspects to get a better understanding on the application and processing of this polymer. Afterwards, the typical properties of the material will be compared to PVB properties. From this information it will become clear in which typical niche applications the use of EVA can have an advantage. Finally, the processing of EVA will be discussed and some typical quality assessment techniques that are not commonly used in PVB analysis will be briefly discussed

EVA chemistry

EVA stands for Ethylene Vinyl Acetate co-polymer. Figure 1 shows the structure of this polymer.

Figure 1: Chemical structure of Ethylene Vinyl Acetate copolymer (EVA).

The polymer is part of the broad polyolefin family where ethylene building blocks (x) are alternated with vinyl acetate blocks (y). The amount of vinyl acetate parts, or VA content, determine the properties of the polymer and is typically in the range of 4% to 40%. The lower the VA content, the more the EVA resembles the properties of a polyethylene which is a typically crystalline polymer. The higher the VA content, the more amorphous the polymer becomes. This has a significant effect on properties such as transparency (the higher the VA content, the more transparent the polymer) and the melting point (the higher the VA content, the lower the melting point). High VA content EVA’s are also softer and less brittle. For interlayer and solar encapsulant applications high VA content EVA’s are used with a typical value between 26 and 28%. In the past, also 32–33% VA content polymers were used, but these are nowadays less common. Higher VA content EVA’s usually find application in glue systems.

EVA polymers are thermoplastic polymers and have a distinct melting point between 70 and 75°C in case of a VA content between 26–28%. Above the melting point a thermoplastic polymer is in a melt state with a distinct melt flow, depending on the polymer properties such as chain length and polymer chain branching. In case of the EVA types that are used in, for example building glass applications, the melt flow is quite high and around 25 g/10 min as measured in a melt flow index meter, which is a specific test to measure the flow properties of molten polymers.

The low melting temperature and high melt flow of this material has a definite effect during lamination. Especially in applications where a more “liquid” polymer characteristic is needed, EVA could offer a solution. In applications where, for example, large voids need to be filled, it could be interesting to consider EVA. This also explains why the main application field of EVA lamination foils is in the lamination of crystalline photovoltaic modules, where a molten polymer needs to fill gaps between cells. The application of EVA in comparison to PVB will be discussed later in this document.

As described, a low melting point has certain implications during lamination, but it also influences the service life of the glass laminate. A temperature of 75°C can be easily reached in certain environments, where even a service temperature of as high as 100°C is no exception. This can result in a melting of the EVA polymer and when the laminate is not properly protected by a frame it can lead to delamination of glass panes.

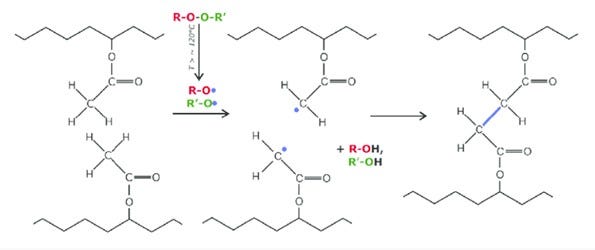

Therefore, for exterior applications, the formulation of EVA with a cross-linking system is desired. Such cross-linking system is used to link polymer chains to each other. The actual melting of these linked polymer chains is not possible anymore and the interlayer remains solid at high operation temperature. As will be discussed later in this document, the cross — linking takes place at the end of the lamination cycle, after the melting and flowing of the EVA. Figure 2 shows a schematic representation of the cross-linking mechanism.

Figure 2: Cross-linking mechanism of EVA, using peroxide chemistry[1].

The cross-linking initiator that is used is a peroxide-based system. Depending on the specific nature of peroxide used, the speed at which the reaction is taking place can be altered. People talk about standard (or normal) cure, fast cure, or even ultra-fast cure. For architectural application usually slower curing peroxides are used, where the ultra-fast curing mechanisms are mainly applied in photovoltaic module lamination. The lamination process determines which peroxide curing system can be used as not all lamination processes are suitable for e.g., ultra-fast curing.

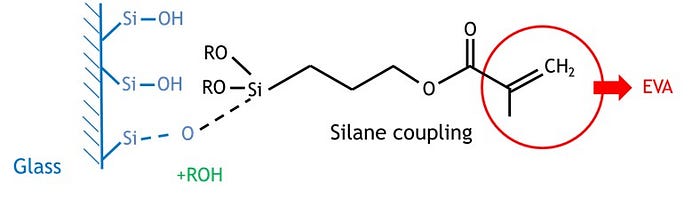

Another important difference in the chemistry between EVA and PVB is the adhesion system. PVB is mainly getting its adhesion to glass via hydrogen bonds of the hydroxyl groups of the PVB-film to silanol groups of the glass. This also means that, when additional moisture is added to this system, it can interfere with the H-bridge between the glass and the hydroxyl groups of the polymer. The adhesion mechanism of PVB is therefore water sensitive and reversible. This is not the case for EVA. EVA is naturally not adhering to glass surfaces. It does not contain a hydroxyl functionality like PVB. Therefore, an organosilane adhesion promotor is added to the polymer. Figure 3 shows the mechanism of this organosilane adhesion promotor.

Figure 3: Schematic representation of the adhesion mechanism of EVA interlayer foils.

There is a lot of literature on glass surface, but for this paper this would bring us too far. In essence, the glass surface consists of a so-called gel-layer with silanol terminating groups and water. The organosilane coupling agent which is mixed in the EVA interlayer has two sides. The silane side reacts with the silanol groups on the glass surface, resulting in the release of alcohols. This bonding is a covalent, thus irreversible, bond. This is a big difference with the earlier described PVB system. The other side of the coupling system contains a double bond functionality that can react with the EVA backbone. The organic side will also entangle with the EVA polymer. The silane coupling can also be used to bond to metal surfaces and EVA can also adhere to other polymer surfaces. In case of the latter, it is however sometimes necessary to design certain tie-layer polymers to facilitate a polymer-polymer bond.

In case of PVB, the adhesion level to the glass surface can be fine-tuned by adding certain salts to the PVB matrix. The ions in the salt interfere with the H-bonds. This fine-tuning of the adhesion level is beneficial as during an impact on the glass laminate the PVB interlayer can release from the glass surface and thus it absorbs a part of the impact energy. Combined with the fact that PVB has a high tensile strength (see further), it is an excellent material for safety glass applications. This is more difficult in the case of EVA as alterations in the concentration of the silane coupling agent do not necessarily scale in a linearway. It is a chemical adhesion mechanism and a bit an all-or-nothing situation. One can influence the actual level a little bit by reducing the silane coupling agent concentration in the EVA polymer, but here lower concentrations very quickly lead to instable, uncontrollable, adhesion levels. Although the adhesion of EVA interlayers to a glass surface is relatively high (> 100 N/cm in a 180° peel test), it cannot be easily controlled.

EVA and PVB properties compared and link with applications

As discussed in previous section, the formulation of EVA is important in relationship with the properties during lamination. In what follows a brief comparison with PVB will be made. Table 1 shows a brief comparison of some interesting properties between both polymers.

Table 1: Brief comparison of some properties between PVB and EVA.

From Table 1 it is clear that the thermal properties of both polymer systems are distinctly different. As discussed earlier, EVA is a thermoplastic polymer which means that it has a distinct melting point. In principle when crossing this point the polymer will be in a completely molten state. The opposite is also true; when the polymer is cooled it will — in principle — solidify, but due to the presence of a peroxide crosslinking system this is not the case anymore for most commercially available EVA’s used in architectural glazing applications. There are also EVA’s out there for interior application that do not contain a crosslinking system, but most of them do contain peroxides.

After passing approximately 130°C, the EVA polymer will crosslink which prevents melting in outdoor applications. PVB is not a pure thermoplastic polymer, it also has elastomeric properties. This means that there is not a distinct melting point and cross-over to a purely molten state. When this material is heated it will become softer and softer.

Next to this, also the melt flow index (MFI) difference between both polymers is very different. In case of PVB it is relatively low, even when a higher weight of 5 kg is applied. The MFI for EVA is, considering the lower weight, a lot higher. This means that when the EVA polymer is molten it is also very “liquid”, whereas the PVB polymer will be in a rubbery state at higher temperature and will flow a lot less. Therefore, EVA is very suited for applications where large voids need to be filled. An example is the application of glass with a deep surface structure where voids need to be filled. In case of (thick PVB) layers, the lack of flow of this polymer can result in bubble formation in the voids. Another application can be found in the encapsulation of for example fabrics or metal meshes between interlayers. Figure 4 shows an example. Due to the high flow of EVA, all microscopic voids can be filled efficiency.

Figure 4: EVA laminates with encapsulated fabric (above), copper mesh (middle) and printed fabric (below).

Next to the excellent flow of EVA, also the adhesion to metals, due to the silane system, which was explained in previous section, makes the encapsulation of metal inserts and meshes in glass laminates a typical application field for EVA.

Another large difference in thermal properties is the glass transition temperature (Tg). For raw PVB polymers this is rather high (around 50°C) which makes PVB a brittle polymer. Therefore, a plasticizer is added to reduce the Tg to around 6 -20°C. The Tg for EVA is very low and is situated in the range of -40°C to -30°C. This makes EVA a very soft material compared to PVB. The softness has implications on mechanical loads on one hand, but on the other hand this low Tg makes EVA very suited for (very) low temperature applications.

If we compare the mechanical properties in Table 1, also a large difference in Tensile strength and elongation can be observed. The tensile strength of PVB is considerably higher than this of EVA. This means that the PVB material shows an additional strength compared to EVA. Also, EVA has a much higher elongation at break making it a much more flexible material. For impact performance applications PVB is the better choice as it can be a stronger interlayer polymer. Table 2 shows a comparison of the impact performance of two EVA brands and a PVB brand.

Table 2: EVA and PVB impact resistance

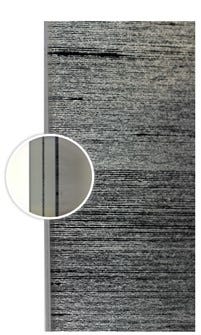

Both polymers show similar optical performance. Both interlayers have a refractive index that is close to the refractive index of glass (1.52), and this makes these material especially suited for use as interlayer materials. As discussed before, EVA is a very amorphous polymer resulting in a high transmittance of light and low scattering that could result in haze formation. The transmittance of EVA is at 91% very good and makes the polymer suited for highly aesthetic applications where low haze is desired. However, al lot depends on the processing of the laminate, and more specifically, to the speed at which the laminate is cooled. The slower the speed, the more time the polymers get to form small crystalline regions in the amorphous bulk of the material. These microscopic crystalline islands can scatter light and results in the formation of haze. EVA interlayers are very sensitive to this phenomenon because they have a larger polyethylene content. Therefore, a forced cooling can be appropriate to choose when using EVA as an interlayer, especially in combination with thick glass panes. If cooling is under control, crystal-clear laminates can be obtained using EVA due to its amorphous structure.

Yellowness, or color in general, in PVB can have many reasons going from processing related degradation to color caused by certain additives in the polymer. The discussion of color in interlayers is outside the scope of this paper, but in general color needs to be well controlled by the interlayer manufacturer. This is done by controlling the manufacturing process, but also by selecting the right additives in the interlayer formulation. This is certainly also the case for EVA. In the past, EVA had the bad reputation to become easily yellow or even brown. The polymer contains acetate groups and, due to heat and moisture hydrolysis of these groups, can lead to the formation of acetic acid which can cause severe chemical reactions. Next to this, also unreacted peroxides can cause problems. Especially in combination with other polymers or metals this can cause severe bubble formation and color. Nowadays the discoloration of EVA is less of a topic as modern stabilization additives can mediate the polymer degradation much better, but one should still be vigilant as not all EVA interlayer manufacturers have the same high-quality standards.

A lot has been written before on moisture uptake of interlayers. PVB is notoriously known to be moisture sensitive in the laminate and if open laminate edges need to be developed, extra attention is needed. As discussed earlier, the adhesion mechanism of PVB to glass is reversible due to the H-bonds on the glass surface. PVB is delivered by the manufacturer with a certain adjusted moisture content. This adjusted moisture content is important as it will determine the initial adhesion level in the laminate. Next to this, from Table 1, it is clear that PVB can take up quite a lot of moisture looking at the water vapor transmission rate (WVTR) and the moisture uptake of this polymer. In, for example open edge applications, moisture can be taken up causing swelling and adhesion reduction of the PVB during the service life of the laminate. When the edges dry out again, the PVB interlayer shrinks and a progressive adhesion crack between glass and interlayer occurs. In case of EVA this is different. EVA is produced as dry as possible. Moisture is avoided at all costs where even the quenching of the material after extrusion is done as dry as possible. This is because the organo-silane adhesion promotor should not react with moisture before it can react with the glass surface. After processing, the bonding between glass and EVA is irreversible. EVA, a polyolefin material, does not take up water as easily as PVB (as can be seen in Table 1) and when it does, the adhesive bonding between the glass surface and the interlayer is much more resistant. EVA is a suited material for open edge applications. Connected to the lower moisture uptake of EVA are the better electrical insulation properties.

To summarize, EVA has distinctly different properties compared to PVB. Both interlayer materials have their specific application field. Being a strong, less flexible and harder material, PVB is especially suited for safety glass applications. The material can absorb impacts very well and, as discussed in previous section, the adhesion can be fine-tuned to such level that it can release from the glass upon impact. EVA on the other hand is a soft, transparent material that has superior flow characteristics. Its adhesion system is irreversible and not as sensitive to moisture. All of this is especially interesting for decorative and aesthetical application where one would like to encapsulate for example all sorts of inserts (fabrics, metal meshes, metal inserts, polyester films, …) in a laminate. In general, a lot of different colors and designs are available in the market and therefore EVA is an interesting alternative to PVB for especially interior and exterior design features. By far the largest market for EVA foils is the photovoltaic market (which will not be discussed in this paper). Due to the high flow (filling gaps between crystalline cells and connectors), crosslinking system (long service life in difficult conditions) and very good electrical properties, this polymer is especially suited for this application, although also certain projects in the architectural market can benefit from this interlayer too.

Processing of EVA

Handling and lay-up

EVA is moisture sensitive when not laminated yet and therefore in general a moisture tight, aluminum lined packaging is used, although also opaque polyethylene bags are used. The foils need to be stored in these moisture tight bags and the temperature of the storage room needs to be below 35°C to avoid roll blocking. It is however not necessary to store the rolls in a refrigerated warehouse such as in case of PVB. Although the temperature can cause self-sticking, it is not to the same magnitude as in case of PVB. In case the temperature cannot be controlled below 35°C (warm, tropical regions) it is advised to order EVA with a thin interleave foil, but in general it is not necessary.

Extra attention needs to be devoted to the shelf life of this interlayer, however. For PVB the “advised best used before time” is in general 3 years, but this does not apply for EVA due to the presence of the adhesion promotor and cross-linking system. Both are sensitive additives and can deteriorate quickly in the not processed foil over time. Therefore, most EVA foil manufacturers advice a shelf life of 9 months to maximum one year, which is considerably shorter than PVB. A commonly asked question is if EVA can still be processed after its expiry date. This should be avoided, because next to the fact that the manufacturer will no longer give any guarantees, the chance that bubbles can be formed during processing or even during the service life of the laminate is rather large. On top of this it is also possible that expired materials can show low adhesion.

There are no special requirements necessary for handling EVA in the lamination lay-up room. Airconditioning or moisture control is generally not really required, but one need to avoid that moisture can condensate on the EVA sheet, which is the same for PVB processing. When EVA material is taken out of the packaging it should be used immediately and leftover materials should be re-packed after use. As a general rule of thumb one can say that the EVA should not stay in the open for more than 8 hours.

During lay-up of the sheet, it is a common practice for EVA to cut the sheet to the same width than the glass pane. In some cases, maximum 5 mm can stick out, but usually not more. EVA does not shrink and deform in the same way than PVB and should not be compensated for on the edges. Due to the high melt flow of the EVA, the material also better handles tempered glass edge curling and other local deformations of the glass. Next to this, when EVA sticks out too far out the edges, it can fold and melt on the outer surface, complicating post processing (see further).

Lamination

In general, EVA processes quite well in vacuum oven processes. Roller processes cannot be used for EVA laminate de-airing. Due to the low melting point and high melt index of the material, the EVA will flow much easier than PVB. In a nip roller process the EVA would just be squeezed out of the glass panes (like marmalade in a sandwich). De-airing is generally done in a vacuum process. This can be a vacuum oven process, a vacuum laminator process or by use of (disposable) vacuum bags in combination with an autoclave.

EVA foils have an embossed surface structure. In case of EVA the surface structure is embossed (pressed) in the surface during cooling down of the melt. This gives a broad range of design freedom and typically every manufacturer has its own embossing design. Also, the surface structure is generally deeper compared to PVB and well controlled, making the de-airing of the laminate quite manageable. In many cases the surface embossing can even be asymmetrical, with a rough side on one side and a smooth side on the other. This is usually the result of an asymmetrical embossing roll design in the EVA extrusion line and has in general limited real advantage (but also no disadvantage). A small advantage is that when laying up the EVA sheet with the rough side towards the glass surface, one can still move the interlayer to position which can be interesting for manual lay-up lines. The opposite is true when laying up on the smooth side. The foil is fixed better (“tackiness”) and will not move during transport. Usually this is preferred in fully automated lines.

The largest market for EVA foils is the photovoltaic module lamination market. The vacuum lamination method employed for PV panel production is by far the most used method for EVA foils. PV lamination systems have been described in a pervious paper, but it would bring us too far to describe the lamination of EVA films in PV-modules in such types of laminators. The main disadvantage of using a PV laminator for architectural glass is the limitation size. PV modules are usually in the range of 1.7 to 2 m² and therefore the lamination machines are usually designed for such size.

Very often EVA interlayers are laminated using vacuum bag ovens. Here the assembly is inserted in a (silicone or single use nylon) vacuum bag and closed. Next, the vacuum bag is shifted in an oven. There are many cycles possible. Due to its easy de-airing and high flow EVA is quite forgiving for the lamination parameters. Things can get more complicated when inserts are added in the laminate. Here the lamination parameters need to be fine-tuned in an experimental way.

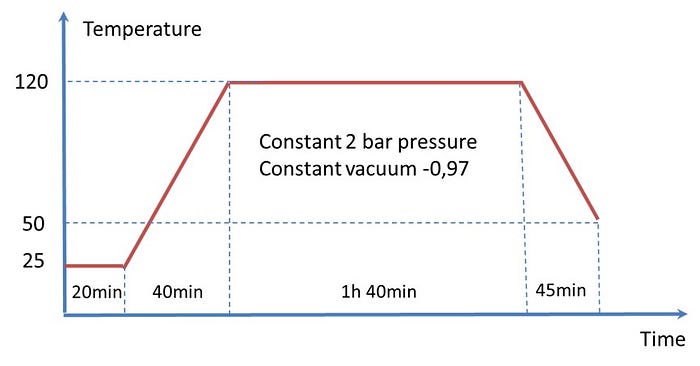

A typical vacuum oven process for EVA starts with a cold vacuum at room temperature (20°C), where usually the vacuum is kept for 30 minutes per square meter laminate surface. Then the vacuum bag can be heated up to 85°C in 30 minutes. In a second step, the oven is heated up further to 130°C — 150°C, depending on the specific case (curing system, laminate complexity, laminate size, …). When a lot of flow is needed, like in case of glasses with a deep surface structure, higher temperature is preferred. The high temperature needs to be maintained for 1 to 3 hours, depending on the thickness of the glass and the curing degree of the EVA. After lamination the laminate is cooled down under vacuum until 40°C, after which the interlayer is cold enough to release the vacuum. In case this cooling period is not respected, it might be possible that the soft EVA interlayer is not strong enough yet when air rushes in, which can cause edge defects. Figure 5 shows a schematic representation of a typical EVA lamination program using a vacuum oven method.

Figure 5: A typical vacuum oven lamination program for EVA lamination.

EVA is ideally suited for autoclave-free vacuum oven manufacturing. It is often the interlayer and method of choice when complex laminates with structured and/or curved glass and/or inserts need to be processed due to its good flow properties.

In case of PVB lamination, autoclaves are often used in combination with nip roller processes and sometimes vacuum bag/ring de-airing. In the autoclave process the increased temperature and pressure are used to dissolved left-over air that is not removed in the pre-process in the PVB matrix. De-airing of EVA interlayers is less cumbersome. Also, since nip roller processes cannot be used, vacuum methods, that remove air more efficiently, are used. In case of EVA interlayers all air needs to be removed and no additional air bubbles can be present before the laminate is finished at higher temperature. If air bubbles would still be present, they would be frozen in the polymer matrix because the cross-linking system will limit the flow behavior of both polymer and air bubble. If the temperature is reaching the cross-linking temperature eventual remaining bubbles cannot be removed anymore. This means that an autoclave process is not necessarily needed for EVA lamination but if the asset is present in the lamination plant it can be used as a large-scale vacuum oven. High pressure is to our knowledge not really needed.

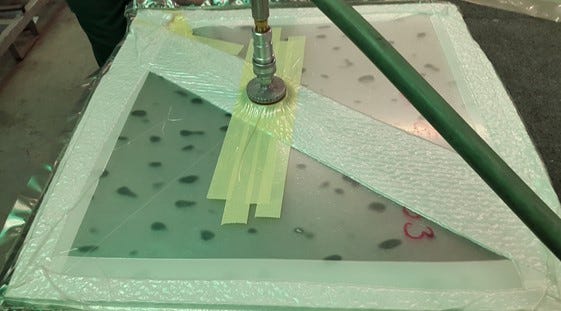

Figure 6 shows an example of a laminate prepared by means of a nylon disposable vacuum bag. The edges of the laminate are wrapped with a combination of woven nylon and cotton fabric to prevent the glass edges to stick through the vacuum bag and also to facilitate air flow at the laminate edges.

Figure 6: preparation using disposable vacuum bags.

These vacuum bags can be transferred into the autoclave. An example of an autoclave program is shown in figure 7. The vacuum bags are kept under constant vacuum and an additional 2 bar is put on the autoclave.

Figure 7: An example of an autoclave cycle for EVA.

Other autoclave programs are also possible, but in general high pressures, long lamination and high temperatures are not needed for EVA lamination. One rule of thumb is that one needs to be sure that all air is out (and remains out) of the laminated before the stacks are heated and full cross linking takes place. One might notice that the autoclave lamination procedure resembles the vacuum oven procedure a lot.

Post processing

Post processing of EVA laminates is usually not difficult. One point of attention is to keep track on EVA spills from the edges. Because of the high flow, edge flow is also very common. In principle such edge spill can be easily removed by trimming, as EVA is a soft polymer as discussed earlier. However, the soft nature can also cause some troubles when the interlayer edges are sticking out of the laminate too far. This can lead to folding and melting of the EVA on the outer surface of the glass pane during processing. These folded sticking strips are sometimes difficult to remove. A splash of isopropanol or acetone can help.

A commonly used tool for trimming of EVA is a heated knife. Although not really necessary, it can ease the work of the operator. In case the EVA is still very flexible during edge trimming or sticks easily to surface, this means that the EVA was not properly cured! More attention should be devoted to optimizing the process in this case. One should check and clean regularly the equipment when using EVA as this material can start to stick and contaminate the workshop easily.

Specific EVA testing

It is not the purpose of this section to list all lab testing that is done on EVA laminates. Many of the typical lab tests for PVB laminates can also be done for EVA laminates. There are however some exceptions and typical features to keep in mind.

A very common adhesion assessment in the laminated glass industry is the Pummel test. The test is performed at a reduced temperature of -18°C because it is well under the glass transition temperature of PVB. At -18°C PVB is quite brittle and adhesive interactions between the polymer and the glass can be assessed better. If the polymer is too soft (above Tg) glass fragments will just be pushed in the polymer bulk and the test is not really indicative only for the adhesion between glass and polymer. Because the Tg of EVA is situated at much lower temperature (between -40°C and -30°C), the classic Pummel test at -18°C is giving a distorted result too. One should cool the laminate at lower than -50°C for example to obtain comparable results, but this is practically not feasible (and is even dangerous). A Pummel test on EVA can be performed at -18°C, but usually, if no large problems occur, the values will always be very high as glass fragments are pushed in the very soft EVA. However, it always makes sense do the test because if there is a real large problem, also very low Pummel values could be observed.

Another adhesion test that is commonly used in the glass interlayer industry is the compressive shear strength test (CSS). CSS testing on EVA interlayers can be done in the same way as in case of PVB laminates, but some caution is needed when interpreting the results. Due to the softness and elongation (see table 1) of the EVA interlayer it is more easily deformed during the shear test. Some of the energy is stored in the deformation of the interlayer in a different way than in case of the stiffer and stronger PVB. Therefore, in first instance, EVA and PVB CSS results cannot be compared to each other. Next to this, if we remember the mechanical properties in Table 1, the tensile strength of EVA is considerably lower than the PVB values. This might lead to an easier cohesive break during the test. Although more theoretical study is probably needed on this topic, it could be possible that one is not measuring the real adhesive strength, but that rather cohesive failure in the material is determined. Compressive shear strength determination of EVA samples usually gives quite high values, but it is not sure if these values tell the true story.

A more straightforward test to measure EVA adhesion is a peel test. Both 180° and 90° peel tests are used, but the 180° test is most probably the least complicated to perform. For this test a laminate is made with glass — EVA and a backsheet material that brings additional stiffness in the test. This backsheet material can be a photovoltaic backsheet (PET based, not polyolefin-based). The glass is fixed on the bottom of the test equipment and the peel arm consist out of the EVA and the backsheet. One can see the test setup below in Figure 8. As the CSS always return high values for EVA laminates and few differentiations is obtained, the peel test usually gives a good representation of the adhesive strength between glass and EVA. For a good quality, EVA values of more than 80 N/cm should be obtained, but usually peel values of more than 100 N/cm can be seen.

Unfortunately, it is difficult (to our knowledge) to do the peel test for PVB samples as PVB shows limited adhesion to polymeric backsheets or metal foil backings.

Figure 8: Picture of a 180° peel test.

Another very typical EVA property is the gel content which is an assessment of the crosslinking density. If the processing time was too short, or something went wrong during lamination (for example too low temperature due to specific circumstances) the peroxide system will not have reacted. This will result in an uncured material and as we described earlier this can lead to failures during the service life. There are a few ways to assess the cross-linking density, but the following methods will show accurate and repeatable results: gel content determination by means of a Soxhlet extraction and a differential scanning colorimetry (DSC) measurement. The DSC method is a quite advanced technique and will not be discussed in this paper in detail. It can be used to do relative measurements of the remaining curing potential of a sample.

The Soxhlet extraction method is most probably the most straightforward and most used way to measure the gel content. In this extraction method a pre-weighted sample of cured EVA is placed in a warm solvent such as Xylene or Toluene. It brings us too far to discuss the Soxhlet method in detail, but the extraction apparatus is constructed in such way that fresh solvent is cycling over the sample. Cross-linked EVA will not dissolve in the hot solvent, but not cross-linked material will. After an extraction time of typically 8 hours the EVA sample is taken out of the apparatus and dried in an oven. The left-over EVA is properly crosslinked, and the ratio of the initial weight and left-over weight is called the gel content. Preferably the gel content of a properly cured EVA should be above 75% to guarantee good ageing behavior of the EVA.

Figure 9: Picture of a running Soxhlet extraction apparatus.

[1] Drawing from Ch. Hirschl et al., Solar Energy Materials & Solar Cells 152 (2016) 10–20